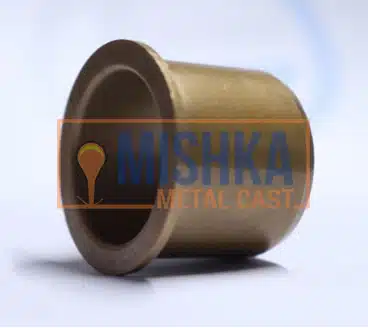

Centrifugal Castings Manufacturer

The centrifugal casting is casting method used for thin-walled cylinders by pouring the molten metal into a preheated spinning die which is either oriented on a vertical axis or a horizontal axis. A centrifugal force is applied when the molten metal is being distributed in the molds while the mold is spinning. Mainly, the metals, glass and concrete are casted in the centrifugal casting. Besides, iron, aluminum, nickel, copper, steel, stainless steel are used in the centrifugal casting. The centrifugal casting is a cost-effective method for manufacturing complex shapes with low machine requirements. There are different types of centrifugal castings used according to the applications. Our collections of centrifugal castings are nickel aluminum bronze castings, gun metal castings, phosp bronze castings, manganese bronze castings, silicon bronze castings. The centrifugal castings are used in different application areas of aircraft, automobile, electronics, petroleum processing plants, power plants. All the centrifugal castings equipments are manufactured with top quality raw materials.